Introduction to Three-Layer Buttons

Three-layer buttons are an innovative and increasingly popular choice in various industries, known for combining enhanced durability, aesthetics, and functionality. These buttons are uniquely constructed with three distinct layers, each serving a purpose to bolster the button’s overall performance. Typically used in apparel, accessories, and upholstery, three-layer buttons have gained traction due to their superior properties compared to traditional buttons.

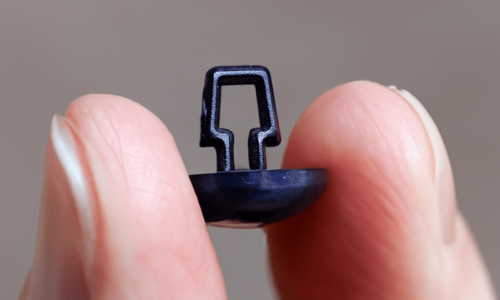

The construction of a three-layer button involves an inner core, an intermediate layer, and an outer layer. The inner core provides a solid foundation, ensuring the button can withstand significant wear and tear. The intermediate layer often imparts additional strength and may comprise materials like metal or reinforced plastic. Finally, the outer layer offers the desired aesthetic appeal, with various design options available to suit different fashion or decor preferences.

One of the primary advantages of three-layer buttons is their increased durability. Conventional buttons can break or deform under pressure, but three-layer buttons’ robust construction allows them to endure more stress. This makes them particularly suitable for high-use garments and furnishings. Further, the versatility in design achievable through the multiple layers allows manufacturers to create buttons that are both functional and stylish, catering to a wide range of consumer tastes.

In addition to durability and aesthetics, the use of three-layer buttons enhances the overall functionality of garments and other products. For instance, in the apparel industry, these buttons ensure garments remain secure and maintain their appearance over time, even after repeated use and laundering. Similarly, they offer reliable fastening solutions in accessories like bags and crafts.

As the demand for high-quality, durable buttons grows, the role of three-layer button manufacturers in India becomes more prominent. These manufacturers are adept at producing buttons that meet stringent quality standards, ensuring their widespread use across multiple sectors. By understanding the construction and benefits of three-layer buttons, it becomes clear why they are a preferred choice among industry professionals.

The Manufacturing Process of Three-Layer Buttons

The production of three-layer buttons by leading manufacturers in India is a complex and meticulous process, reflecting both traditional craftsmanship and modern technology. The journey begins with the selection of high-quality raw materials, which typically include a variety of plastics, metals, and sometimes even custom-designed outer layers. These materials are chosen based on their durability, aesthetic appeal, and compatibility with the intended final product.

The initial stage of the manufacturing process involves cutting and shaping these raw materials. Advanced machinery is used to ensure precision and consistency in the dimensions of each layer. In this phase, the individual components that will make up the three-layer buttons are meticulously crafted to exact specifications. This stage is crucial because any discrepancies can affect the overall functionality and appearance of the finished buttons.

Once the raw materials are prepared, the assembly of the button layers begins. This process requires a high degree of precision and expertise, as the layers must align perfectly to ensure the button’s structural integrity and aesthetic quality. Three-layer button manufacturers in India employ a combination of automated assembly lines and skilled manual labor to achieve this. The technology used here ensures that the layers are securely bonded together, often using specialized adhesives or fastening techniques.

Following assembly, the buttons undergo a finishing process. This involves polishing, coating, and sometimes adding final design touches such as embossing or engraving. These finishing steps not only enhance the appearance of the buttons but also add an extra layer of protection against wear and tear. Quality control measures are rigorously enforced throughout this stage to ensure that every button meets industry standards and customer specifications.

The emphasis on innovation and quality control in the manufacturing process underscores the capability of three-layer button manufacturers in India to produce high-grade, reliable products. By integrating advanced machinery with skilled craftsmanship, these manufacturers are able to meet the diverse needs of their clients while maintaining the highest standards of quality and efficiency.

Market Trends and Demand in India

In recent years, the demand for three-layer buttons has surged significantly across India, reflecting a broader trend within the fashion and textile industries. This growth can be attributed to several factors, including evolving fashion trends that emphasize unique and durable garment components. As a result, three-layer button manufacturers in India are seeing increased business from both domestic and international clients.

A key driver of this demand is the rising consumer awareness regarding the quality and durability of clothing fasteners. Three-layer buttons are known for their robustness and aesthetic appeal, making them a preferred choice for premium and everyday apparel alike. The diverse functionality and strong consumer preferences underline why three-layer button manufacturers in India are in the spotlight, particularly in metropolitan hubs such as Delhi where fashion and textile innovation thrive.

To cater to this growing need, manufacturers are increasingly offering customization options. This includes variations in color, size, material, and design, enabling brands to align their fasteners’ features with their specific requirements. The flexibility provided by three-layer button manufacturers allows designers and brands to differentiate their products in the marketplace effectively.

Volume production capabilities and quick turnaround times are equally crucial in responding to market demands. Three-layer button dealers in Delhi and other key locations are capitalizing on advanced manufacturing technologies to ensure they can meet large orders without compromising on quality. This efficient production process helps in maintaining a steady supply, thereby catering to the just-in-time inventory needs of the fashion industry.

The booming interest in these buttons is also reflected in the growing number of small and medium enterprises entering the market, thereby providing a wider range of choices for consumers and businesses. The diverse offerings of three-layer button manufacturers in India play a pivotal role in fulfilling the complex needs of various sectors, from fashion to utility apparel, further strengthening this manufacturing segment’s position in the Indian market.

Choosing the Right Manufacturer

When selecting three-layer button manufacturers in India, several critical factors should be considered to ensure you make the most informed decision. Quality should be at the forefront of the selection criteria. High-end manufacturers often adhere to stringent quality control standards, ensuring that each button meets specific durability, performance, and aesthetic requirements.

Experience is another pivotal aspect. Established manufacturers typically have in-depth knowledge and expertise in creating three-layer buttons, which often translates to superior products. Investigating the manufacturing capacity of potential suppliers is also crucial. Ensure they are capable of handling your order volume, meeting deadlines, and scaling up production if necessary.

Adherence to industry standards and achieving relevant certifications are key indicators of a reputable manufacturer. Certifications such as ISO can provide assurance that the company meets international quality management standards. Checking for these certifications can give you confidence in the manufacturer’s commitment to quality.

Customization capabilities are also essential. The ability to tailor products to specific design and functional needs can provide a significant competitive advantage. This includes variations in material, size, and color, or the incorporation of specific branding elements. Understanding the design capabilities of a manufacturer will help you gauge whether they can meet your unique requirements.

In addition, evaluate the manufacturer’s client portfolio to gauge their reliability and reputation within the industry. A strong portfolio with well-known clients often signals consistent performance and satisfaction. Practical tips for evaluating potential manufacturers include asking for samples to assess quality firsthand and requesting client testimonials to gain insights into real-world interactions.

Ultimately, choosing the right three-layer button manufacturers in India involves a thorough assessment of these factors. By focusing on quality, experience, capacity, standards, and customization abilities, you can make a well-informed decision that aligns with your specific needs.